Case study: DATA & ANALYTICS

Boost Productivity and Profitability Using Advanced Analytics

Case Study at a Glance

Client

A world leader in manufacturing rolled aluminum products

The Problem

To cope with the challenges of high energy costs and reduced profitability

Solution

Harnessing data from MES, inspections, and lab tests to enhance final product quality

Results

Anticipated to drive first-year savings in the Multi-Million-Dollar range, boost productivity by 10-20%, and achieve a remarkable 25% increase in recovery.

The Customer:

A world leader in manufacturing rolled aluminum products, it provides high-quality, reliable, and innovative products for the automotive and industrial sectors.

With a significant market share In North America, they are one of the players in realizing the unlimited potential of aluminum alloys that are used in the energy efficiency-focused automotive industry.

The Challenge:

Aluminum manufacturers, like other manufacturing companies, are currently coping with the challenges of high energy costs and reduced profitability.

It is imperative that to be successful, these companies need to strive for higher margins through lowering energy wastage, improving productivity, and higher efficiency of operations.

One challenge presented to us was about the high percentage of scrap and rework due to poor quality of the product that is detected only during testing of the completed product.

If the quality can be assessed early, it can help with reducing wastage of manufacturing resources.

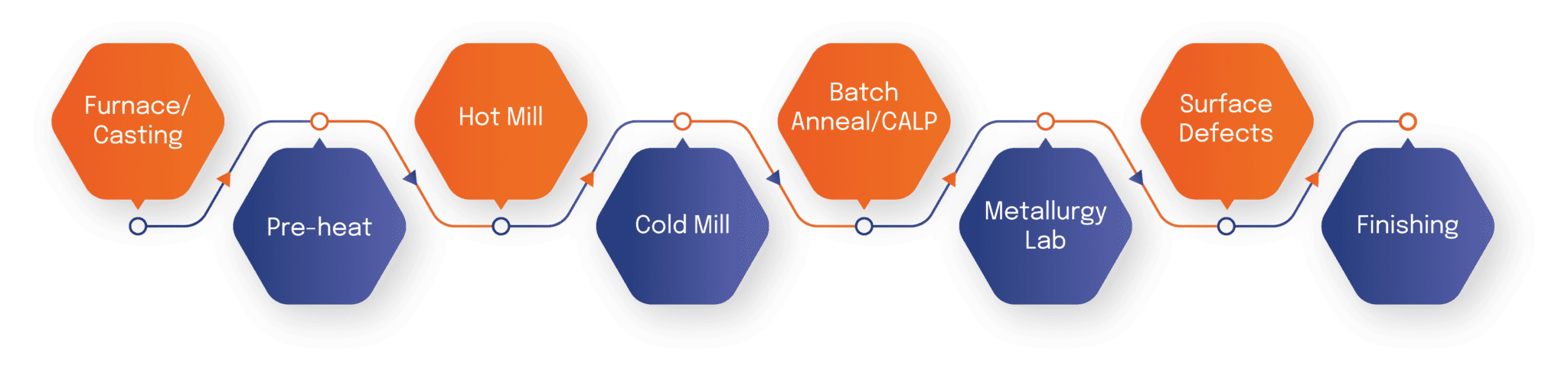

Manufacturing a coil of aluminum is a multi-day or even a multi-week process, as shown below.

The quality of the coil that is produced is dictated by a variety of factors at each stage of the process – factors such as temperature, rolling pressure, humidity, and so on.

The quality of the ultimate coil that is produced is additive from one stage to the next.

Most mature coil manufacturers have MES systems that capture significant amounts of data at each stage of the manufacturing process.

These data hold significant insights into the evolving quality of the coil as it goes through the process steps.

If the data at each process step can be marshaled and analyzed to provide information about the quality of the coil at the end of each process step, the line operators can make real-time decisions about the coil and subsequent actions.

The Solution:

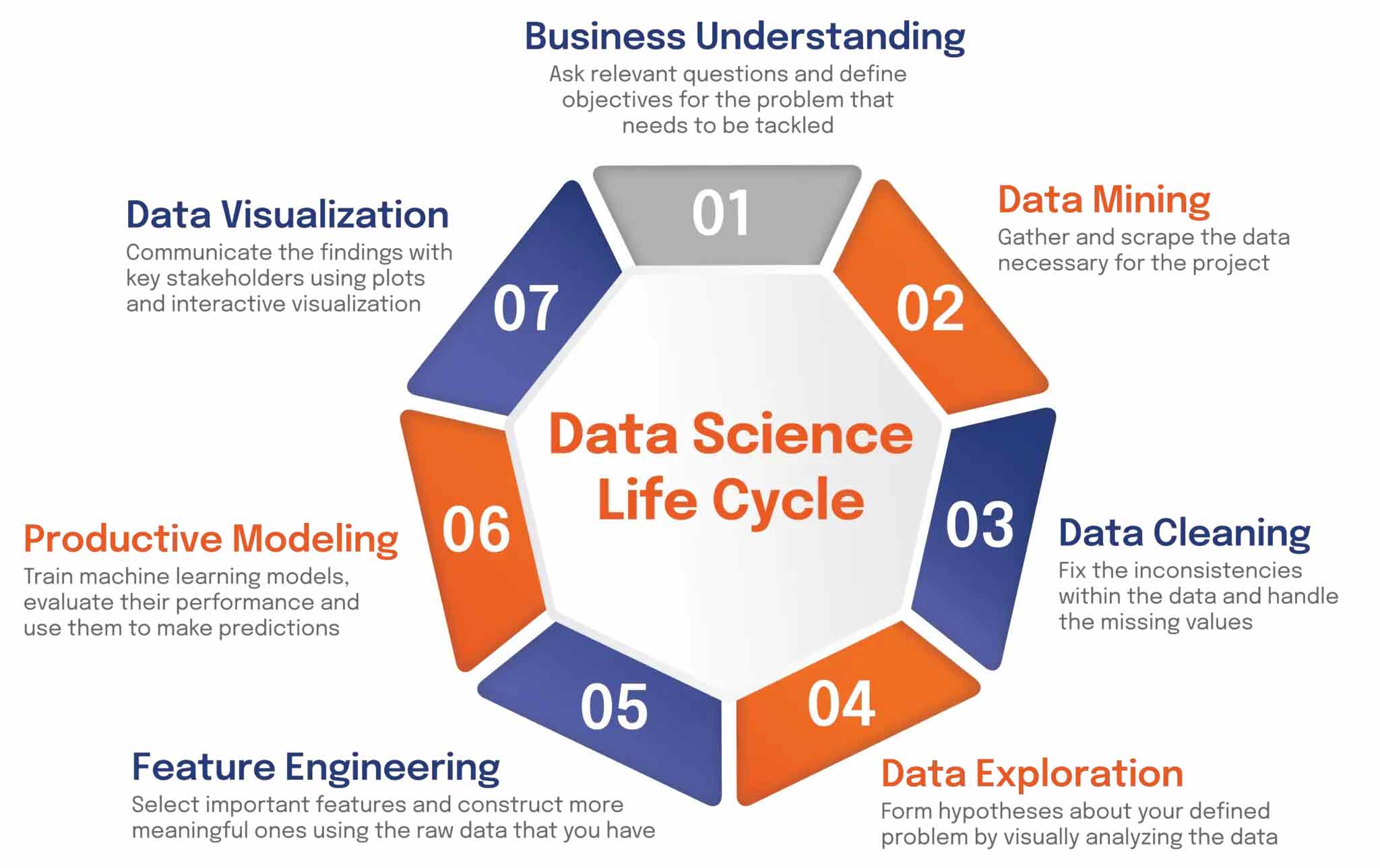

Vertex proposed a solution that includes collecting data from MES (Manufacturing Execution System), quality inspections and lab test data and using proven data science techniques to study the impact of various conditions that impact final product quality.

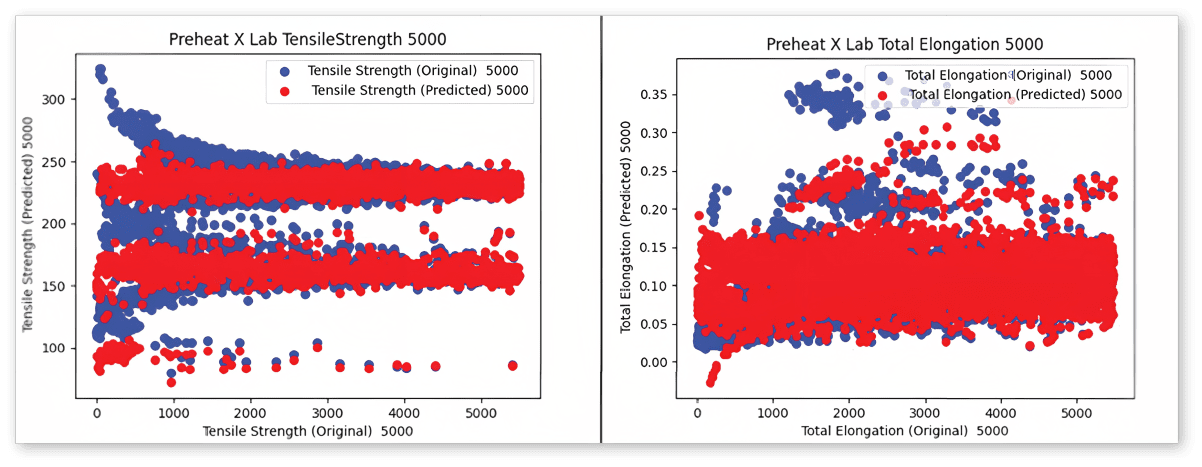

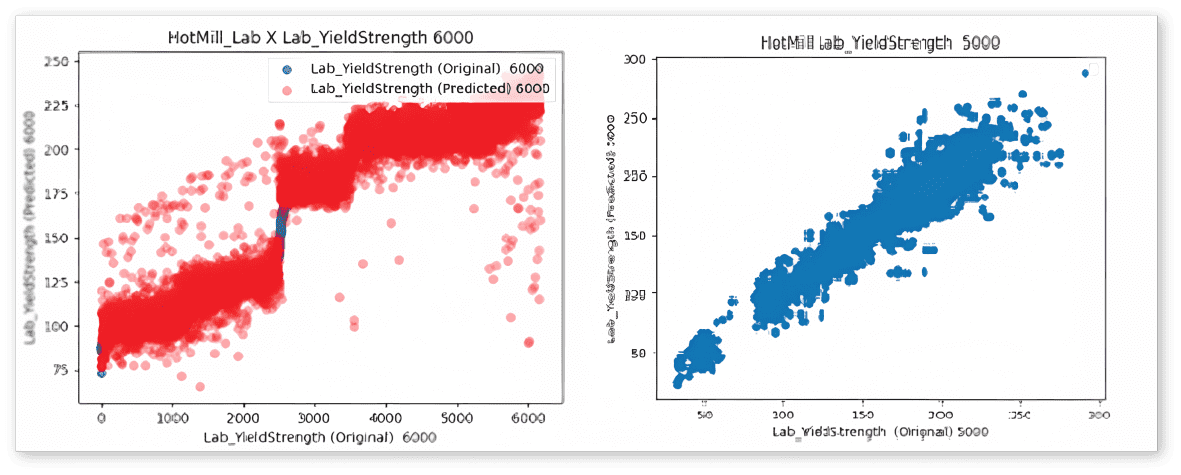

We developed a model that can assess the quality at the end of each process step and predict the final quality properties with more than 90% Accuracy.

To develop the quality prediction model, we collected historical data from the manufacturing process and lab testing and applied data science to determine the factors that impacted coil quality at each step of the manufacturing process.

Once the model was developed, we operationalized the model by incorporating the analysis with real-time manufacturing data.

The solution now collects data from all process steps, such as the furnace, pre-heat, hot mill, cold mill, annealing, and finishing, to deliver an accurate prediction and impactful insight into root causes, thus eliminating rework costs.

The Implementation:

The biggest challenge to the project was accessing the data that was siloed across several systems.

Our Data Engineers had to thread together the various pieces of data through sophisticated ETL and cleansing algorithms so that the Data Science module could have the data in real-time.

The mix of different alloy types was another challenge. Our model now predicts with more than 90% accuracy across all the alloys that are used.

Results:

The solution provides an in-process prediction model that is more than 90% accurate. Our prediction results are validated by product testing and metallurgy SMEs.

Once the solution is completely rolled out, it will provide a cost avoidance of approximately $50,000 per bad coil.

Our solution is expected to create multi-million-dollar cost savings during the first year of operation, improve productivity by 10-20%, and increase recovery by 25%.